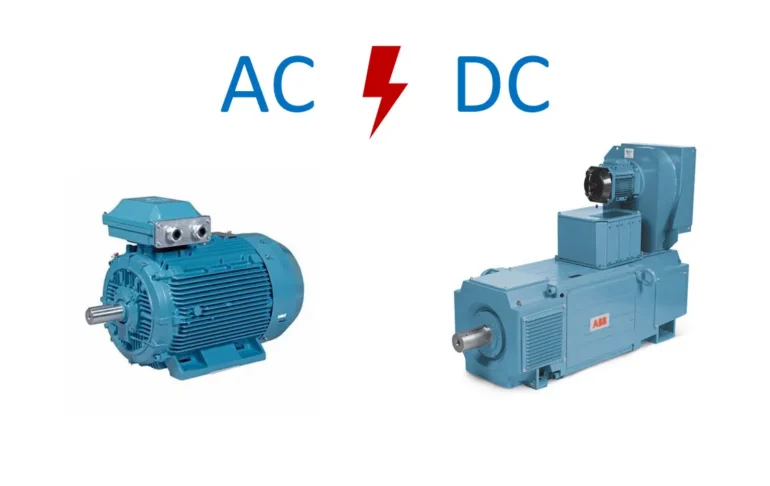

When it comes to controlling the speed and torque of motors in various applications, AC DC drives play a crucial role. From industrial machinery to home appliances, these drives are essential for efficient and precise motor control. In this blog, we will explore what AC and DC drives are, how they work, their differences, and their applications. Let’s dive in and understand these important components in simple terms.

What are AC Drives?

AC drives, also known as variable frequency drives (VFDs) or inverters, are devices used to control the speed of an AC motor. They operate by modifying the frequency and voltage of the power delivered to the motor. This enables the motor to run at various speeds, allowing for enhanced control over its operation.

How Do AC Drives Work?

AC drives convert the fixed frequency and voltage of the electrical supply into variable frequency and voltage. Here’s an idea of how they work:

- Rectification: The AC power from the main supply is converted into DC power using a rectifier.

- Filtering: The DC power is then smoothed using filters to reduce any ripples or noise.

- Inversion: The filtered DC power is converted back into AC power, but with variable frequency and voltage. This is done using an inverter.

By changing the frequency of the AC power, the speed of the AC motor can be controlled. This allows for precise adjustments to match the specific requirements of the application.

Applications of AC Drives

AC drives are used in various applications where speed control is essential. Some common uses include:

- HVAC Systems: Heating, Ventilation, and Air Conditioning systems use AC drives to control the speed of fans, pumps, and compressors, improving energy efficiency.

- Industrial Machinery: AC drives are widely used in manufacturing processes to control conveyor belts, mixers, and other machinery.

- Elevators and Escalators: These drives ensure smooth and safe operation by controlling the speed and torque of motors.

- Renewable Energy: AC drives are used in wind turbines and solar power systems to optimize performance.

What are DC Drives?

DC drives are devices used to control the speed and torque of DC motors. They work by regulating the voltage and current supplied to the motor. DC drives are simpler in design compared to AC drives and have been used for many years in various applications.

How Do DC Drives Work?

DC drives control the speed of a DC motor by adjusting the voltage and current. Here’s how they operate:

- Power Conversion: The AC power from the main supply is converted into DC power using a rectifier.

- Voltage Regulation: The output voltage is regulated to control the speed of the motor. Increasing the voltage increases the speed, while decreasing the voltage reduces the speed.

- Current Control: Current is adjusted to control the torque of the motor. Higher current results in higher torque.

DC drives offer straightforward control over motor speed and torque, making them suitable for specific applications that require precise control.

Applications of DC Drives

DC drives are commonly used in applications where precise speed and torque control are necessary. Some examples include:

- Cranes and Hoists: DC drives provide smooth and precise control, which is essential for lifting and moving heavy loads.

- Electric Vehicles: Many electric vehicles use DC drives for their motors due to their simple design and effective control.

- Printing Presses: DC drives ensure consistent speed and torque for high-quality printing.

- Rolling Mills: In the steel industry, DC drives control the speed and torque of rolling mills, providing precise adjustments during the manufacturing process.

Differences Between AC and DC Drives

While both AC and DC drives serve the purpose of controlling motor speed and torque, they have some key differences:

- Complexity: AC drives are more complex due to the need for conversion between AC and DC and then back to AC. DC drives have a simpler design.

- Maintenance: AC motors used with AC drives are typically more robust and require less maintenance compared to DC motors.

- Efficiency: AC drives are generally more energy-efficient, especially in applications with variable speed requirements.

- Cost: DC drives are often less expensive initially, but the overall cost may be higher due to maintenance and operational factors.

Choosing Between AC and DC Drives

Selecting the right drive depends on the specific requirements of your application. Here are some considerations:

- Application Type: Determine if your application needs precise speed and torque control. DC drives are ideal for applications like cranes and electric vehicles, while AC drives are better for HVAC systems and industrial machinery.

- Cost: Consider both initial costs and long-term operational costs. AC drives may have a higher upfront cost but can be more cost-effective in the long run due to lower maintenance.

- Efficiency: For energy-efficient operations, especially in variable speed applications, AC drives are the preferred choice.

Conclusion

AC and DC drives are essential components in modern motor control systems. They provide the flexibility and precision needed to match the requirements of various applications. By understanding the basics of how they work, their applications, and their differences, you can make informed decisions about which drive is best suited for your needs. Whether it’s for industrial machinery, HVAC systems, or electric vehicles, choosing the right drive can significantly impact the efficiency and performance of your operations.