In the sector of industrial automation and system manage, the DCS Distributed Control System stands out as a cornerstone generation. It is used in quite a few industries, inclusive of power technology, oil and fuel, pharmaceuticals, and production, to streamline tactics and beautify efficiency. This weblog will dive deep into the idea of DCS, its additives, benefits, and actual-global programs, ensuring you recognize why it’s fundamental in current industries.

What is a DCS Distributed Control System?

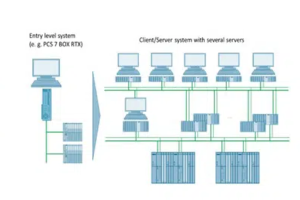

A DCS Distributed Control System is an advanced system control device that distributes control features across a network of interconnected devices as opposed to relying on a unmarried centralized controller. This decentralized architecture guarantees better reliability, scalability, and performance in coping with complicated industrial processes.

At its core, a DCS is designed to:

- Automate industrial processes.

- Provide centralized monitoring and control.

- Enhance operational safety and efficiency.

Unlike traditional control systems, a DCS focuses on distributing control and monitoring tasks to various subsystems, ensuring that each operates independently while still being connected to the main network.

Components of a DCS Distributed Control System

Understanding the key components of a DCS Distributed Control System is essential to grasp how it functions effectively:

- Control Modules: These are the coronary heart of the DCS, chargeable for executing manage good judgment and coping with method variables. Each module operates independently however communicates with others seamlessly.

- Human-Machine Interface (HMI): The HMI serves because the consumer interface, allowing operators to screen procedures, regulate parameters, and troubleshoot troubles in real time.

- Engineering Workstations: These are used for configuring and programming the device, making it adaptable to numerous commercial wishes.

- Field Devices: Sensors, actuators, and transmitters that accumulate facts and execute instructions in the area.

- Communication Network: A strong communique network guarantees seamless facts switch between all components, the use of protocols like Ethernet or proprietary solutions.

Advantages of Using a DCS Distributed Control System

The DCS Distributed Control System offers numerous benefits that make it a preferred choice in industrial automation:

- Reliability: With its decentralized architecture, the gadget minimizes the chance of general failure. If one module malfunctions, others retain to operate independently.

- Scalability: DCS structures can effortlessly adapt to the developing desires of a plant, taking into consideration the addition of latest manipulate modules or strategies with out big reconfiguration.

- Improved Process Control: By dispensing manipulate tasks, the device gives particular and consistent management of complicated processes, enhancing product great.

- Centralized Monitoring: Operators can oversee all tactics from a unmarried region, making it easier to discover and deal with troubles promptly.

- Enhanced Safety: Advanced protection capabilities, which include alarms and emergency shutdown systems, are incorporated into the DCS to shield both personnel and gadget.

- Energy Efficiency: By optimizing method control, the DCS reduces electricity consumption and operational charges.

Applications of DCS Distributed Control System

The versatility of a DCS Distributed Control System makes it suitable for a wide range of industries. Here are some of its most common applications:

- Power Generation: DCS systems are used to manage boilers, generators, and different critical strategies in energy plant life, ensuring green and dependable energy era.

- Oil and Gas: From upstream exploration to downstream refining, DCS structures play a essential role in controlling operations, monitoring equipment, and making sure safety.

- Chemical and Petrochemical Industries: In those industries, specific manipulate of chemical reactions and approaches is crucial, making DCS an invaluable device.

- Pharmaceuticals: DCS systems make certain compliance with stringent first-class standards with the aid of presenting correct control and tracking of manufacturing procedures.

- Water Treatment: Municipal and commercial water remedy facilities depend on DCS systems for efficient operation and compliance with environmental policies.

- Food and Beverage: In this quarter, DCS structures optimize production processes, preserve hygiene requirements, and improve product consistency.

How Does a DCS Distributed Control System Work?

The operation of a DCS Distributed Control System revolves around its ability to collect, process, and distribute data across various components. Here’s a step-by-step overview:

- Data Collection: Field gadgets together with sensors measure parameters like temperature, stress, and float price.

- Data Processing: Control modules manner the amassed information, evaluating it to setpoints and making vital adjustments.

- Command Execution: Actuators and other subject gadgets execute commands primarily based at the control good judgment, making sure the system remains within favored parameters.

- Monitoring and Feedback: The HMI shows real-time facts, allowing operators to monitor methods and provide remarks if guide intervention is needed.

- Continuous Improvement: Engineering workstations analyze ancient records to identify trends, optimize tactics, and improve device performance.

Key Features of Modern DCS Distributed Control Systems

Modern DCS Distributed Control Systems come equipped with advanced features that enhance their functionality and usability:

- Integration with IoT: Many DCS systems now help Internet of Things (IoT) gadgets, allowing faraway tracking and predictive upkeep.

- Advanced Analytics: Built-in analytics equipment help operators become aware of inefficiencies and capacity issues, enhancing choice-making.

- Redundancy: To make certain uninterrupted operation, modern DCS systems provide redundant additives, including energy components and communique networks.

- Cybersecurity: With increasing threats, DCS structures now encompass strong security features to guard against cyberattacks.

- User-Friendly Interfaces: Intuitive HMIs make it simpler for operators to interact with the gadget, lowering the learning curve.

Choosing the Right DCS Distributed Control System

Selecting the right DCS Distributed Control System for your needs involves considering several factors:

- Industry Requirements: Different industries have precise desires, so pick out a system designed to handle your particular processes.

- Scalability: Ensure the device can develop along with your operations, accommodating destiny expansions.

- Budget: Evaluate the whole price of ownership, such as initial funding, maintenance, and improvements.

- Vendor Reputation: Partner with a reputable seller that gives reliable assist and offerings.

- Technology: Opt for a system that includes the modern-day technology, making sure lengthy-time period relevance and efficiency.

Conclusion

The DCS Distributed Control System is a transformative generation that has revolutionized commercial automation and process manipulate. Its decentralized architecture, coupled with superior features, makes it an quintessential device for handling complex operations throughout numerous industries.

Whether you’re in electricity generation, prescription drugs, or manufacturing, making an investment in a DCS can appreciably enhance efficiency, protection, and profitability. To explore modern-day DCS solutions, visit NMA Group and find out how this technology can take your operations to the following stage.

By information the competencies and blessings of a DCS Distributed Control System, you’re better geared up to make knowledgeable selections that pressure operational excellence.