Firms today are largely reliant on motor control and automation to enhance efficiency. AC DC drives are among the most important components of motor control systems. AC/DC drives are used to control the speed, torque, and power of electric motors and are hence a requirement across various applications from domestic appliances to machinery.

What Are AC/DC Drives?

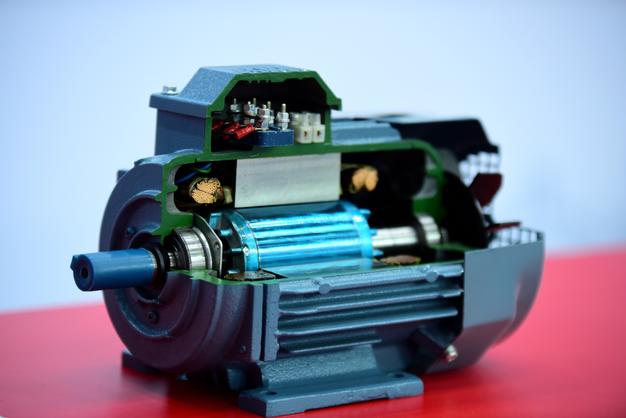

AC/DC drives are speed and motor operation controllers of electric motors. AC DC drives convert electrical energy to a useful form for a motor. The two main types of AC drives (or variable frequency drives, or VFDs) and DC drives exist:

AC Drives: They control AC motors through variation in the power voltage and frequency provided. They find application in fans, conveyor belts, pumps, and air-conditioning systems.

DC Drives: They control DC motors by adjusting the voltage and current to the motor. They are used in applications such as elevators, electric cars, and robots.

AC DC drives play a vital role in increasing energy efficiency, reducing wear and tear, and improving performance.

How AC/DC Drives Function

Let us simplify how AC/DC drives function:

Power Conversion:

AC drives accept input AC power and convert it to DC just to convert it again to regulated AC output.

DC drives accept direct current (DC) power and alter the voltage supplied to the motor.

Speed Control:

AC drives control motor speed by varying the supply frequency.

DC drives control motor speed by varying the voltage.

Torque Management:

The motor supplies the correct amount of force needed to perform the task via drives.

Through the use of AC/DC drives, companies are able to achieve more accuracy and savings in energy costs, leading to better productivity.

Benefit of AC DC Drives

There are numerous benefits to using AC/DC drives for most applications:

Efficiency of Energy:

The drives conserve energy by varying the speed of the motor instead of always running the motor at its capacity.

Improved Performance:

Precise speed control improves smoother operation, reducing mechanical stress and prolonging equipment life.

Cost Effectiveness:

Less energy consumption implies reduced electricity bills. Also, less wear and tear implies reduced maintenance expenses.

Automation and Control:

Drives enable automation in factories, greater precision, and less intervention.

Environmental Benefits:

Less power consumption implies less carbon footprint; hence, operations become environment-friendly.

Applications of AC DC Drives

AC/DC drives are used in various industries and applications, including:

Manufacturing: Robot arms, conveyor belts, and other equipment are driven by drives.

HVAC Equipment: AC drives are utilized to drive fans, pumps, and compressors in a manner such that they power them and make them economical.

Electric Vehicles: DC drives have a significant contribution towards motor speed control and the battery.

Renewable Energy: Solar panels and windmills employ drives to control energy production.

Mining and Drilling: Heavy-duty motors are powered by AC/DC drives for smooth drilling equipment operation.

Choosing the Right AC/DC Drive

Choosing the right drive is based on a number of factors:

Motor Type: An AC drive pairs with AC motors, and a DC drive pairs with DC motors.

Power Requirements: Determine voltage and current requirements of your application.

Control Features: Look for speed control, overload protection, and remote capability.

Environmental Operating Conditions: Choose the drive capable of operating in temperature, humidity, and dust conditions under which it will run.

Maintenance and Diagnosis

AC/DC drives should be serviced from time to time to ensure they deliver long-term performance. Below are some pointers:

Clean it: Dust and dirt could inhibit its performance, so clean the drive from time to time.

Check connections: Malfunction due to a loose wire is a possibility, so check electrical connections from time to time.

Watch temperature: Overheating can ruin components, so give them proper ventilation.

Update software: Firmware upgrades that promote efficiency have been provided with some new drives.

Check for warning signs: Random vibration, unusual sound, or unexpected power-down may be indications of a fault and need to be repaired.

Future of AC/DC Drives

AC DC drives will gain more traction as industries are automated and they move towards energy-saving options. Drive technology will improve further with advancements such as integration with artificial intelligence, predictive maintenance, and wireless control.

Conclusion

AC DC drives have important applications in motor control with their effectiveness, precision, and affordability. AC DC drives maximize performance and energy consumption in industrial equipment, household appliances, and electric cars. AC/DC drives will continue to become more advanced, effective, and imperative to utilize as technology continues to evolve.